- Sheetcam tool library torchmate install#

- Sheetcam tool library torchmate update#

- Sheetcam tool library torchmate software#

- Sheetcam tool library torchmate code#

I suspect you possibly have the same output assigned in Mach for flood coolant and spindle/torch. Saying that my table still works fine, a M8 should not turn on you torch, I would say you have a setup or a wiring issue with your machine or Mach3.

Sheetcam tool library torchmate install#

I tried to install Torchmate CAD but without a. but would need the library to compile against.

Sheetcam tool library torchmate code#

Maybe only the G Code for torch on and off will need to be tweaked. Hopfully someone at autodesk can look at this issue. I will have to create a simple tool path in both Torchmate and Sheetcam then compare them line by line to see the difference.

Sheetcam tool library torchmate update#

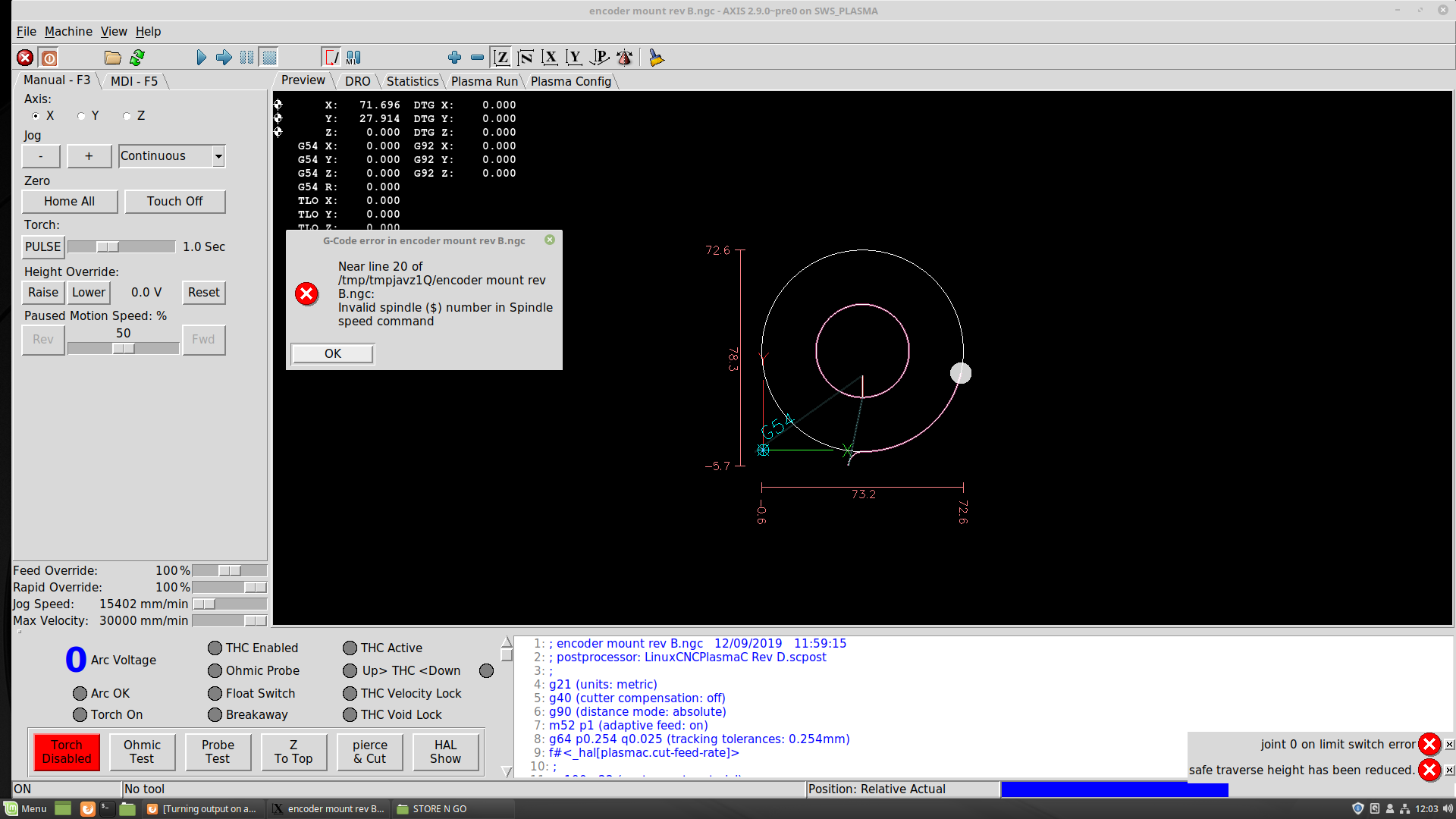

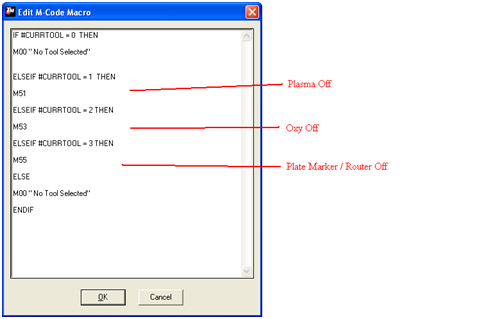

in tool library the post processor tab Milling tools etc have a coolant selection for post processing but cutting tools do not, It seems to me since the update cutting tools have defaulted to flood coolant but there is no coolant drop down selection or parameters to turn it off. I had a look through the code and the torchmate post processor has a coolant lookup table, this is due to it being used for both milling a profile cutting but I Think the problem is with the Tool Library in Fusion360. Hi, I just checked & mine is also now adding a M8 instruction since the fusion update. I've had to go in and modify the g code manually to change it back to M9 to get me by. Any suggestions? Do I have mach3 set up wrong? I've tried to find some where in the tool library in fusion360 where I have something with the plasma and coolant configured wrong with no luck. I looked up M8 is to turn on the flood coolant on and M9 is to turn it off. Before the update the third line was N30 M9.

To unzip the folder, right click and select "extract all" from the drop down menu.I had your post processor working great on my homemade plasma table, Thank you. But just updated fusion360 and now when I post using this same post processor the third line in the code is N30 M8 which for some reason turns on the torch on my machine. Once it does its first touch n go it turns on and off like it should. I can save as in many different file formats.įolders are zipped to reduce download time. If you need a certain file format, email and let me know. Depends on what I "saved as" the day I made it. Plasmaspider ~ robinhillmachine What do I get?Įach download contains a DXF, SVG, and a JPG proof. RTC is free to join and is a forum run by SignTorch. They are the best forums for sharing plasma DXF files. You can also download some of my free files on Ready To Cut and Plasma Spider. I cannot guarantee these will work for your intended purpose.

Make sure my files will work with your equipment before investing money. You have to go through checkout to get them, but there is no charge. I charge an additional $15 to resize premade files. If you need help resizing files, contact me at and let me know which file you need and what size you plan to cut it. This may involve removing some of the details and moving some nodes if you plan to cut small. Some of these files are not designed with any specific cut size in mind so be prepared to adjust as needed for your material thickness and kerf width. If you make the files smaller, you will need to adjust the spacing. If you make the files larger you shouldn't have any issues. If you see "will cut at (size) with 0.15" minimum spacing" they are cut ready.

Sheetcam tool library torchmate software#

Import it into your software and make sure my design style works with your cutting system. While these files are designed specifically for CNC plasma, they MAY work for other applications such as Cricut, Silhouette, vinyl cutting, water jet, laser, and other personal cutting machines.

This section is for digital downloads only.

0 kommentar(er)

0 kommentar(er)